SUPREME - TR 8017 S

-

Load capacity

270 kg

595 lbs

(Load capacity is based on < 10.000 cycles) -

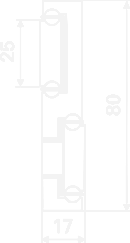

Width

17 mm

0.67 inch -

Height

80 mm

3.15 inch -

Travel

full extension 100%

The Supreme - TR 8017 S Design is one of our slimmest extra heavy duty telescopic ball bearing drawer slide with a full extension up to 100%. Manufactured from cold drawn high grade steel the Supremes steel extra heavy duty slides ensure strong raceways, fit for the industrial applications they were designed for. The Supreme - TR 10020 S-Design extra heavy duty slide has been designed to work under conditions of extreme shock. The slim fitted extra heavy duty slide of 17mm has a big advantage, in comparison to the other slides, that it takes less mounting space allowing a wider drawer to be installed.

Combine the Supreme - TR 8017 S Design with another slim slide from our product range such as the Ulf, Titan and TR-7619 Jumbo. This extra heavy duty slide is highly suitable to the electronic racking industry; machine building, industry, railway and special vehicles applications, automotive, industrial machines.

- High load rating up to 270 kg

- Very robust and compact design

- Standardized hole pattern

- Length and extension customizable by request

- Sold per piece, not per pair!

These different types of extra heavy-duty Supreme slides, together with the Supra- and TR-7619 slides, enlarge our robust and rigid super heavy duty slide range for applications such as; machine building industry, railway and special vehicles applications, medical equipment, automotive, packaging machines, industrial machines and more!

Supreme 13880S* S-design in steel

|

Article number

|

Installation

length "L

mm/inch |

Extension

length "T"

mm/inch |

Load capacity

per pair (kg)

kg/lbs |

Drill table

|

||

|

A

|

B

|

C

|

||||

|

13880S79

|

200 mm / 7.9”

|

200 mm / 7.9”

|

270 kg / 595,2 lbs

|

50

|

||

|

13880S80

|

250 mm / 9.8”

|

250 mm / 9.8”

|

265 kg / 584,2 lbs

|

50

|

50

|

|

|

13880S81

|

300 mm / 11.8”

|

300 mm / 11.8”

|

260 kg / 573,2 lbs

|

50

|

100

|

|

|

13880S82

|

350 mm / 13.8”

|

350 mm / 13.8”

|

255 kg / 562,2 lbs

|

50

|

150

|

|

|

13880S83

|

400 mm / 15.7"

|

400 mm / 15.7"

|

250 kg / 551,2 lbs

|

50

|

200

|

|

|

13880S84

|

450 mm / 17.7”

|

450 mm / 17.7”

|

245 kg / 540,1 lbs

|

50

|

250

|

|

|

13880S85

|

500 mm / 19.7"

|

500 mm / 19.7"

|

240 kg / 529,1 lbs

|

50

|

300

|

|

|

13880S86

|

550 mm / 21.6”

|

550 mm / 21.6”

|

230 kg / 507,1 lbs

|

50

|

150

|

|

|

13880S87

|

600 mm / 23.6"

|

600 mm / 23.6"

|

225 kg / 496 lbs

|

50

|

175

|

|

|

13880S88

|

650 mm / 25.6”

|

650 mm / 25.6”

|

220 kg / 485 lbs

|

50

|

200

|

|

|

13880S89

|

700 mm / 27.6”

|

700 mm / 27.6”

|

215 kg / 474 lbs

|

50

|

225

|

|

|

13880S90

|

750 mm / 29.5”

|

750 mm / 29.5”

|

210 kg / 463 lbs

|

50

|

250

|

|

|

13880S91

|

800 mm / 31.5”

|

800 mm / 31.5”

|

190 kg / 418,9 lbs

|

50

|

275

|

|

|

13880S92

|

850 mm / 33.5”

|

850 mm / 33.5”

|

180 kg / 396,8 lbs

|

50

|

300

|

|

|

13880S93

|

900 mm / 35.4”

|

900 mm / 35.4”

|

170 kg / 374,8 lbs

|

50

|

325

|

|

|

13880S94

|

950 mm / 37.4”

|

950mm / 37.4”

|

160 kg / 352,7 lbs

|

50

|

350

|

|

|

13880S95

|

1000 mm / 39.4”

|

1000 mm / 39.4”

|

150 kg / 330,7

|

50

|

375

|

|

other lengths are available upon request

Supreme Steel Slides

Supreme Steel Slides are manufactured from high grade steel type C45 E+C which ensures a slide with strong raceways, fit for the industrial purpose they were designed. Plating is ROHS compliant. Steel beams are plated with an industry standard zinc and passivate 10-12 microns surface protection. Standard ball bearings are chrome plated steel balls with an option to upgrade to stainless steel 304 or 316L.

Load Capacity and Deflection

The Supreme range is available in 44 different models which offer extensions from 50% through to 100% and even 200% of the slide’s closed length. We offer bi-directional / bilex extension as standard. Our slides are tested to destruction and we confidently work up to 2000 kg with the largest profiles. Load calculations are based upon 1% deflection of the slides closed length when fully loaded per extended pair. This rises to approximately 2% on our 150% and 200% extension models due to the multiple beams. We recommend that external stops are used within the fabrication on the larger profile slides or those which may be subject to lateral and longitudinal forces. The stops used are limited to speeds not exceeding 0.3 mm/s.

Tested Conditions

The Supreme Range of high strength steel slides has been designed to work under conditions of extreme shock and vibration, particularly applications of under slung battery boxes on trains and heavy drawers on specialist vehicles. The Supreme range has been tried and tested ‘double T’ beam format where strength and rigidity is required with minimal slide deflection.

Standard Program

The extra heavy duty industrial slide range is available either from stock or on short production lead times. As our standard manufacturing process for the Supreme range is taking stock lengths of cold drawn steel and machining to size, we are able to offer ANY size configuration without the need for expensive tooling, even for low volumes. The slides in this range are sold per piece and not per pair.

Supreme TR - 8017 S Design Steel full extension extra heavy-duty telescopic slide for heavy duty load capacities up to 2000 kg. Below you can download the stepfile, pdf and other technical specifications which belong to the Supreme TR - 8017 S Design Steel.