Larder Unit for Heavy Duty

-

Load capacity

300 kg

661.39 lbs

(Load capacity is based on < 10.000 cycles) -

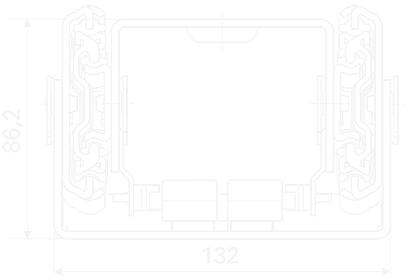

Width

132 mm

5.19 inch -

Height

86,2 mm

3.39 inch -

Travel

full extension 100%

-

Fixations

-

Surface treatments

- Bright zinc chromate - blue passivation

-

General

- Recommended fitting space

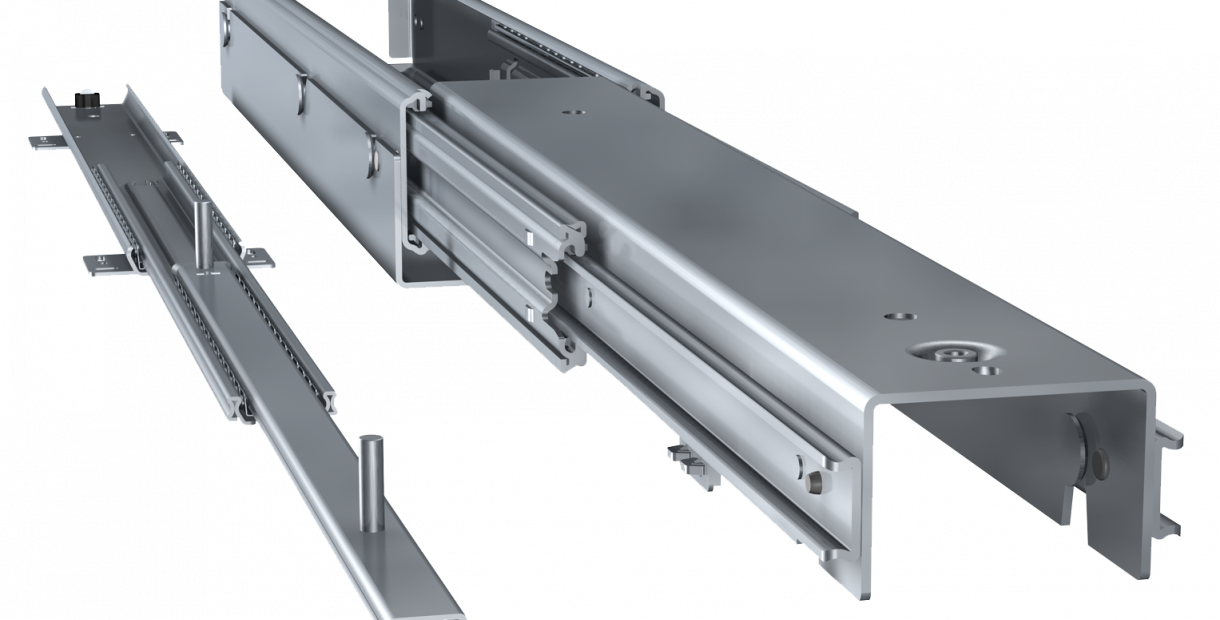

Larder Unit Heavy Duty

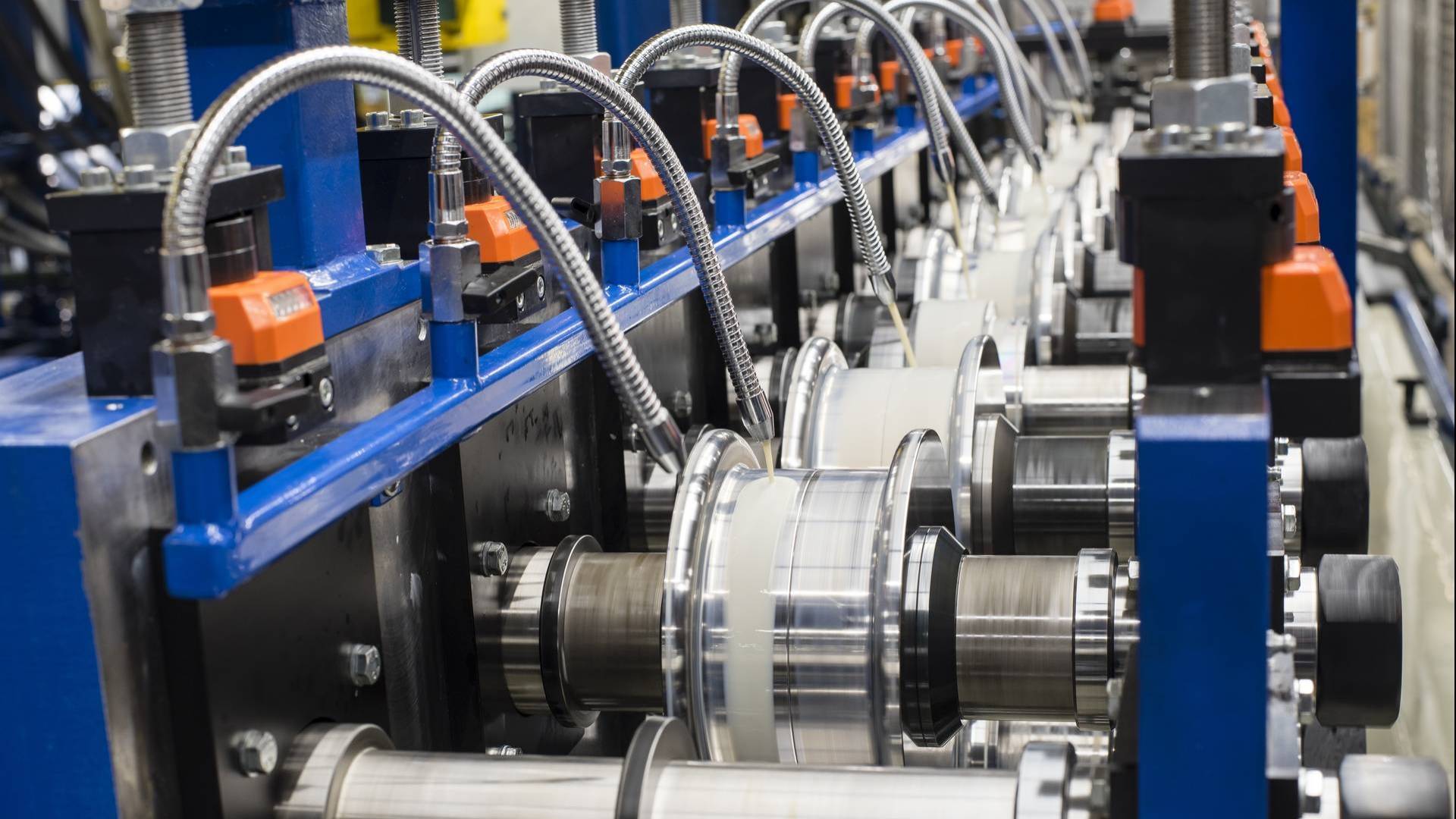

We developed a complete new pull out system together with the TR-7619 slide up to 300 kg with a minimal of deflection as the professional storage market for tooling cabinets demands robust systems with high load capacities. This system offers the highest degree of rigidity, robustness and includes high quality components to guarantee a long life cycle. Slides are partially deliverable from stock.

Load capacity

Load capacity varies as the result of a number of factors. Main factors being the type of slide, length, and ratio between pull-out length and closed length. Another important factor is the number of cycles the slide is required to make. Thomas Regout distinguishes the type of usage between dynamic use and static use. Other factors that influence the load capacity are the features the slide is equiped with, and how it is mounted. Slides are usually mounted sideways so all data concerning load-capacity will be given for sidemounted use. For information about the load capacity with bottom-mounted slides, please contact our sales department.

Dynamic load capacity

In order to determine the dynamic load capacity, all types of Thomas Regout slides have been tested for 100,000 cycles. Their maximum load capacity is compliant with, or exceeds, all common national and international standards including DIN, BIFMA, BS, EN and JIS. The dynamic load capacity figures can be found in the graph below.

Static load capacity

Static load capacity is based on test results at 500, 1000 and 10,000 cycles. This is most common for industrial purposes. The static load capacity is considerably higher than the dynamic load capacity for all slides. The static load capacity figures listed below were determined for a single length of that slide and are for indication purposes only. Specific applications can be assessed by our R&D department and tested if necessary.

Extension

Extension is defined as the ratio of the travel length of the slide (T) and the lenght of the slide in closed position (L): T = (T/L)*100%. The influence of the extension and length of the slide on the load capacity is shown in the graph below

Thermal resistance

Maximum temperature approx. 100°C, determined by applied plastics and lubrication.

Minimum temperature approx. -20°C, determined by applied plastics and lubrication.

Attention: maximum and minimum temperature are strongly determined by the specific application; duration of exposure, impact and other forces on slide and slide components etc. Values mentioned are indicative, it is important to judge each individual application.

Materials

Thomas Regout slides are available in numerous materials and coatings. Below is an overview of all the materials used in our slides. All our products are compliant with EU ROHS standards.

Sections:

- Cold rolled, low carbon and high yield strength steel according to EN 10268 and EN 10139

- Pre-galvanised low carbon and high yield strength steel according to EN 10147 and EN 10139

- Stainless steel according to EN 10088-2 and EN 10259

Ball cages: Electrolitically galvanised, cold rolled, low carbon and high yield strength steel according to EN 10131 and EN 10152

Ball bearings: Hardened carbon steel C15, Kl 4 DIN 5401

Locking features: PA, PE, PBTP, TPU, EPDM

Sequence devices: PA, TPU, PP Bumpers: RR PA, TPU, EPDM

Lubrication: Heavy duty ball bearing grease (free of lead), based on mineral oil

Stainless steel

More and more telescopic slides are used in new applications which requires very high corrosion resistance. Due to this fact, Thomas Regout has created the possibility to supply its total product range in stainless steel according to EN 10088-2 and EN 10259. Please inform us about your requirements to create the slide you need. Surface treatment:Our slides are available in a selection of standard finishes to the specifications listed below. If you require an alternative or specialized finish not listed, please contact us for further information

Surface treatment (finishing)

Our slides are available in a selection of standard finishes. These finishings can be found in the feature list. The overview provides information about which slide can have a specific surface treatment. If you require an alternative or specialized finish not listed, please contact us for further information.

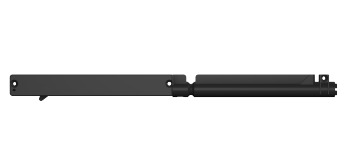

Soft close damper - outside

Soft close damper - outside

Countersunk holes

Countersunk holes